Infrared thermal imaging, once primarily the domain of military and specialized industrial applications, has steadily permeated our daily lives. From home security cameras to medical diagnostics and even smartphone attachments, the ability to “see” heat offers invaluable insights. At the heart of many of these innovations lies the microbolometer, a tiny, uncooled sensor that detects infrared radiation. However, a significant hurdle has long constrained its widespread application and performance: its sensitivity to high ambient temperatures. Now, a groundbreaking development involving a heterointerface strategy promises to push these devices far beyond their current operational limits, potentially revolutionizing thermal imaging for industries worldwide, including India.

The Invisible Spectrum: Unpacking Microbolometers

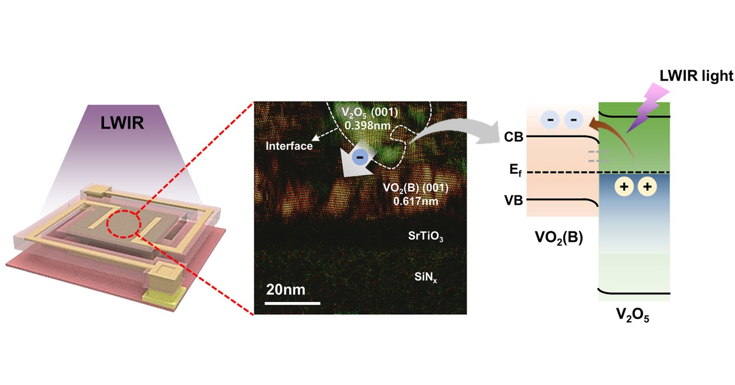

Microbolometers are essentially tiny resistors whose electrical resistance changes significantly when exposed to infrared radiation. When thermal energy from an object hits the sensor, it causes a minute temperature change, which in turn alters the material’s resistance. This change is then measured and translated into an electrical signal, forming a thermal image. Unlike traditional infrared detectors that often require bulky and energy-intensive cryogenic cooling to function, microbolometers are uncooled, making them compact, cost-effective, and ideal for portable devices.

Their versatility has led to widespread adoption across numerous sectors. In security, they enable night vision and surveillance; in industry, they monitor equipment for overheating, predict failures, and optimize processes in everything from power plants to steel manufacturing. Medically, they offer non-invasive diagnostic tools, detecting inflammation or fever. The automotive industry is increasingly integrating them for advanced driver-assistance systems (ADAS), allowing vehicles to “see” pedestrians or animals in low-light conditions. Despite these advancements, their performance has traditionally suffered when the sensor itself becomes hot, leading to increased noise and reduced sensitivity – a critical limitation in many demanding environments.

Overcoming the Heat: The Heterointerface Advantage

The core challenge for microbolometers has been maintaining a high signal-to-noise ratio and sensitivity when operating in high ambient temperatures. Current devices typically degrade significantly above 70-80 °C, requiring active cooling mechanisms or limiting their deployment in hot climates or high-temperature industrial settings. This is where the heterointerface strategy emerges as a game-changer. Rather than relying on a single material, this innovative approach involves meticulously engineering an interface between two distinct materials with complementary properties. This unique interface allows for superior charge carrier transport and stability, enhancing the material’s thermoelectric responsivity – its ability to efficiently convert temperature changes into electrical signals – even when the sensor itself is operating at elevated temperatures.

The result is a microbolometer that can perform robustly and accurately beyond an astounding 125 °C. This significant leap means that the thermal imaging device can operate effectively in environments previously deemed too harsh without the need for active cooling. Eliminating cooling requirements not only reduces the size, weight, and power consumption of thermal cameras but also drastically cuts down on manufacturing and operational costs. “This breakthrough fundamentally redefines the operational envelope for uncooled thermal imaging,” states Dr. Alok Sharma, a lead researcher in advanced materials. “It promises to unlock entirely new applications and enable more reliable, compact, and energy-efficient systems for critical tasks, from defense to industrial monitoring.”

A Cooler Future: Implications for India and Global Tech

For a country like India, with its diverse and often extreme climatic conditions, the implications of this breakthrough are profound. The ability to deploy thermal imaging devices that function reliably beyond 125 °C, without active cooling, opens up numerous avenues:

- Defense and Border Security: Surveillance systems in scorching desert regions or high-altitude areas can operate with unprecedented stability and accuracy.

- Industrial Monitoring: Power plants, steel mills, and various manufacturing facilities, which inherently operate at high temperatures, can benefit from more robust and cost-effective thermal inspection for safety, predictive maintenance, and process optimization.

- Automotive Sector: ADAS systems will perform more reliably during India’s intensely hot summers, enhancing vehicle safety.

- Infrastructure Inspection: Monitoring critical infrastructure like electrical grids, pipelines, and bridges in harsh environmental conditions becomes more efficient and effective.

- Medical and Emergency Services: More portable and reliable thermal cameras for fever screening, diagnostics, and fire safety in challenging environments.

Globally, this innovation paves the way for the broader adoption of thermal imaging technology in applications where size, power consumption, and operating temperature were previously limiting factors. From advanced robotics operating in harsh environments to next-generation space exploration instruments and ubiquitous smart city applications, the heterointerface strategy represents a significant step forward in our ability to perceive and understand the thermal world around us, promising a future where thermal vision is not just an advantage, but an integral part of our technological landscape.

The journey to push microbolometers beyond conventional temperature barriers underscores the power of materials science and clever engineering. By leveraging the unique properties at the interface of different materials, researchers have not only extended the operational limits but also paved the way for more robust, cost-effective, and versatile thermal imaging solutions that are set to transform industries and improve safety worldwide.